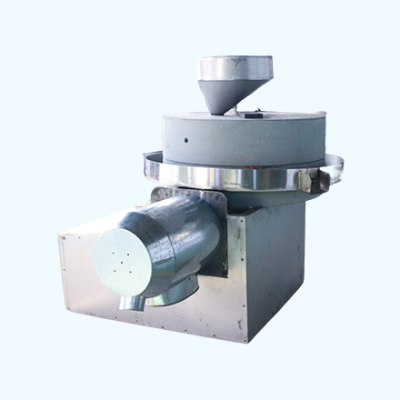

Granular Filling Machine

1. The design of the granule filling machine is easy for daily maintenance, which reduces downtime and further improves production efficiency.

2. The granule filling machine is equipped with a microcomputer control system, which can achieve precise measurement and automatic error correction, further ensuring the accuracy of packaging.

Granular Filling Machine Advantage

1.The granular filling machine can achieve high-speed and stable filling operations, greatly improving production efficiency. Its filling speed can be adjusted according to production needs to meet the production needs of enterprises of different sizes.

2.The equipment is reasonably designed, compact in structure, and easy to clean and maintain. For example, the equipment may be equipped with independent cleaning pipes and material storage boxes, which is convenient for users to perform cleaning and material replacement operations.

3. The granule filling machine has good hygiene and can meet the hygiene requirements of the food, medicine and other industries. This is closely related to the design of the granule filling machine. Its material contact part is made of high-quality stainless steel, which is anti-corrosion, dust-proof and easy to clean, and meets GMP requirements.

Parameter:

| Device Model | Voltage(V) | Power(W) | Max flow(L/min) | Measuring range | Filling error(g) | Filling height(cm) | Equipment weight(kg) | Packing size(cm) |

| Y1-50(liquid) | customize | 200 | 25 | 20g-50kg | ≤5 | 0-40 | 15.5 | 50×35×30 |

| G2-50(Paste) | customize | 250 | 20 | 20g-50kg | ≤5 | 0-40 | 20 | 50×35×30 |

| N1-50 | customize | 550 | 35 | 50g-50kg | ≤5 | 0-40 | 18 | 40×30×40 |

| R1-50 | customize | 750 | 30 | 50g-50kg | ≤5 | 0-40 | 58 | 50×35×30 |

Application scenarios

Restaurant chain enterprises: Restaurant chain enterprises usually need to mass-produce standardized sauce products for use in stores. Granular sauce filling machines can help them achieve efficient and stable filling operations and meet the store's demand for sauce products.

Other related industries: In addition to food processing and sauce production companies, granular sauce filling machines may also be used in other industries that need to fill granular liquids, such as cosmetics, daily chemical products, etc.

Packaging

Packing stage

Choose appropriate packaging materials: According to the size, weight and transportation method of the equipment, choose sturdy and durable packaging materials, such as wooden boxes, metal frames, etc., to protect the equipment from damage during transportation.

Professional packaging: Operated by a professional packaging team or company to ensure that the equipment is properly fixed and wrapped to reduce vibration and impact during transportation.

Identification and labeling: Clearly mark the product name, specifications, quantity, weight, transportation signs (such as handle with care, moisture-proof, etc.) and necessary warning information on the packaging.

Our Customers