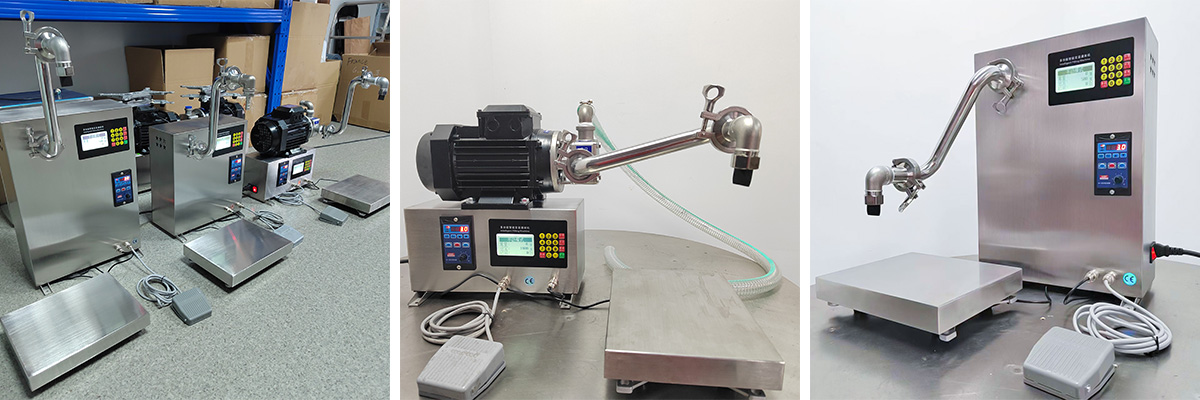

China Semi-Automatic Granule Filling Machine

1.The Semi-automatic filling machine production line is capable of continuously and rapidly completing the filling and packaging processes, significantly enhancing production efficiency.

2.Equipped with precise metering systems and control mechanisms, Semi-automatic filling machines ensure that each container is filled with the exact quantity of product, eliminating errors.

Introduction:

The Semi-automatic filling machine production line is a highly automated production equipment that integrates multiple processes such as filling, sealing, labeling, and inspection, enabling efficient and precise filling and packaging of various product forms including liquids, pastes, and granules.

Parameter:

| Device Model | Voltage(V) | Power(W) | Max flow(L/min) | Measuring range | Filling error(g) | Filling height(cm) | Equipment weight(kg) | Packing size(cm) |

| Y1-50(liquid) | customize | 200 | 25 | 20g-50kg | ≤5 | 0-40 | 15.5 | 50×35×30 |

| G2-50(Paste) | customize | 250 | 20 | 20g-50kg | ≤5 | 0-40 | 20 | 50×35×30 |

| N1-50 | customize | 550 | 35 | 50g-50kg | ≤5 | 0-40 | 18 | 40×30×40 |

| R1-50 | customize | 750 | 30 | 50g-50kg | ≤5 | 0-40 | 58 | 50×35×30 |

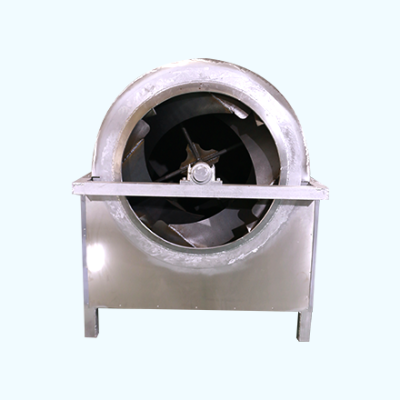

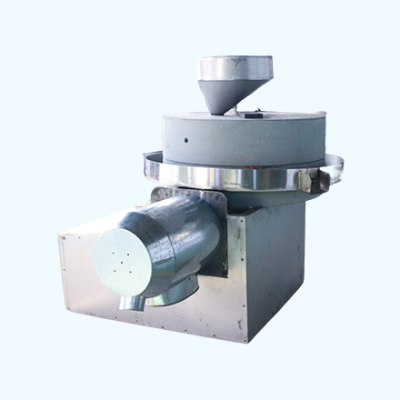

Component:

A Semi-automatic filling machine production line typically consists of several key components:

Filling System: At the heart of the production line, this system is responsible for precisely dispensing products into containers. Depending on the product, various filling methods may be employed, including piston-type, peristaltic pump, gravity-fed, and more.

Container Conveyor System: This system transports empty containers to the filling station and then moves filled containers to the next stage of the process. The conveyor system often utilizes belts, chain plates, slides, or other similar mechanisms.

Capping/Sealing System: For containers that require sealing, the production line is equipped with a capping/sealing system. The sealing methods vary, such as screw capping, press capping, heat sealing, etc., depending on the type of container and the characteristics of the product.

Labeling System: To enhance the aesthetic appeal and identifiability of products, the production line typically includes a labeling system. This system automatically applies labels to designated positions on the containers.

Inspection System: To ensure product quality, the production line also incorporates an inspection system. This system examines factors such as filling volume, sealing quality, label position, and more, promptly identifying and removing any substandard products.

Application Scenario:

The Semi-automatic filling machine production line is widely utilized across various industries including food, beverages, daily chemicals, pharmaceuticals, chemicals, and more. For instance, in the food industry, this production line can be used for filling juices, beverages, condiments, and the like. Whereas, in the daily chemicals industry, it can be employed for filling shampoo, shower gel, cosmetics, and various other products.

Our Customers