Semi Automatic Milk Bottle Filling Machine

1. The semi-automatic milk bottle filling machine adopts weighing filling with high precision.

2. The operation is simple and easy to use.

3. Easy to maintain and clean.

4. Meet the needs of different industries.

5. In stock, it will be shipped immediately after the order is placed.

Semi Automatic Milk Bottle Filling Machine Product Introduction

The weighing semi-automatic filling machine is an environment friendly and correct liquid or viscous fabric filling equipment, which is extensively used in food, chemical, pharmaceutical and different industries. The gear video display units the filling weight in actual time via the weighing sensor to make certain the accuracy and consistency of every filling. It is handy to function and appropriate for the wants of small and medium-sized manufacturing lines. Its semi-automatic format combines the traits of guide loading and computerized filling, which no longer solely improves manufacturing effectivity however additionally reduces the complexity of guide operation.

Product advantages

1. High-precision filling:

The semi-automatic filling computer adopts weighing sensor technology, and the filling accuracy can attain ±0.1%, making sure steady product quality.

2. Easy operation:

The semi-automatic filling computer has a common interface, and operators solely want easy education to get started, decreasing running errors.

3. Strong adaptability:

The semi-automatic filling computer gear is appropriate for a range of beverages and viscous materials, such as sauces, oils, detergents, etc., to meet the desires of distinct industries.

4. Energy saving and excessive efficiency:

The semi-automatic layout reduces power consumption, whilst enhancing manufacturing effectivity and decreasing manufacturing costs.

5. Easy maintenance:

The tools has a easy structure, is convenient to easy and maintain, reduces downtime, and extends the provider existence of the equipment.

Product Use

Weighing type semi-automatic filling machine is widely used in the following fields:

Food industry: used for filling soy sauce, vinegar, cooking oil, sauce and different liquid ingredients to make certain meals protection and hygiene.

Filling tahini, peanut butter, chili sauce and different paste foods.

Chemical industry: appropriate for filling detergents, lubricants, paints and different chemical merchandise to enhance manufacturing effectivity and product consistency.

Pharmaceutical industry: used for filling liquid medicine, disinfectant and different pharmaceutical merchandise to make sure filling accuracy and hygiene standards.

Through its excessive precision, easy operation and huge applicability, weighing kind semi-automatic filling desktop has come to be an perfect preference for a number industries to enhance manufacturing effectivity and make sure product quality.

Parameter

| Device Model | Voltage(V) | Power(W) | Max flow(L/min) | Measuring range | Filling error(g) | Filling height(cm) | Equipment weight(kg) | Packing size(cm) |

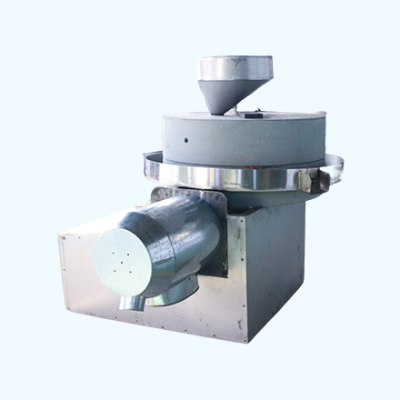

| Y1-50(liquid) | customize | 200 | 25 | 20g-50kg | ≤5 | 0-40 | 15.5 | 50×35×30 |

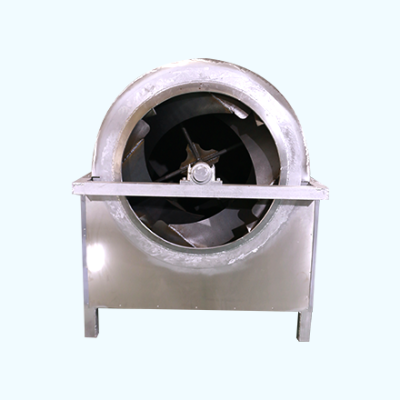

| G2-50(Paste) | customize | 250 | 20 | 20g-50kg | ≤5 | 0-40 | 20 | 50×35×30 |

| N1-50 | customize | 550 | 35 | 50g-50kg | ≤5 | 0-40 | 18 | 40×30×40 |

| R1-50 | customize | 750 | 30 | 50g-50kg | ≤5 | 0-40 | 58 | 50×35×30 |

How to choose a suitable weighing semi-automatic filling machine?

1. Select the model according to the material characteristics.

2. Consider the production scale and efficiency requirements.

3. Pay attention to the accuracy and stability of the equipment.

Our Company