Honey Filling Machine

1. The honey filling machine has a simple structure and is easy to operate.

2. Save manpower, improve production efficiency, and reduce labor intensity.

3. Can fill liquids, pastes and granules.

4. Large flow rate and wide range.

5. The display language is English.

6. One-year warranty and can be shipped at any time.

Introduction:

1.A Honey Filling Machine is a device used to accurately and quickly fill liquids, pastes, powders, and other materials into containers. Its main advantages lie in high automation, high efficiency, easy operation, high filling accuracy, and the ability to adapt to the filling needs of various different materials.

2.Through precise measurement and control systems, the filling machine can ensure the accurate filling amount of each bottle of product, improving production efficiency and product quality.

3.In addition, the filling machine also has flexibility and scalability, which can be adjusted and upgraded according to production needs.

Advantage:

1. Easy operation: The honey filling machine has a simple and reasonable structure and is easy to operate. Even beginners can quickly get started.

2. Save manpower: Semi-automatic operation reduces manpower participation, improves production efficiency, and reduces labor intensity.

3. Wide range of applications.

4. The honey filling machine adopts a precise mechanical structure and advanced electronic control system, which can easily adjust the filling volume, speed and accuracy to ensure that each filling is accurate.

5. Safety protection: The honey filling machine is equipped with a safety protection device to prevent liquid overflow and ensure safe operation.

6. Made of food grade stainless steel pipes, healthy and hygienic.

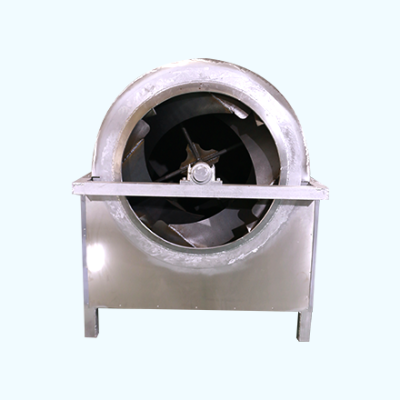

Product Details

Our products can be applied to filling sesame paste, peanut butter, honey, grease, pastes without particles and corrosion, viscous liquids without particles and corrosion, etc.

Usage process:

1. Preparation work 2. Adjusting parameters 3. Starting the filling machine 4. Filling operation 5. Monitoring operation 6. Filling completion 7. Cleaning and maintenance

Parameter:

| Device Model | Voltage(V) | Power(W) | Max flow(L/min) | Measuring range | Filling error(g) | Filling height(cm) | Equipment weight(kg) | Packing size(cm) |

| Y1-50(liquid) | customize | 200 | 25 | 20g-50kg | ≤5 | 0-40 | 15.5 | 50×35×30 |

| G2-50(Paste) | customize | 250 | 20 | 20g-50kg | ≤5 | 0-40 | 20 | 50×35×30 |

| N1-50 | customize | 550 | 35 | 50g-50kg | ≤5 | 0-40 | 18 | 40×30×40 |

| R1-50 | customize | 750 | 30 | 50g-50kg | ≤5 | 0-40 | 58 | 50×35×30 |

FQA

Q: Do you provide customized service

A: We can design the machines according your requirements(materil ,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

Q: When will it be shipped?

A: It is in stock and will be shipped immediately after payment is made

Our Customers

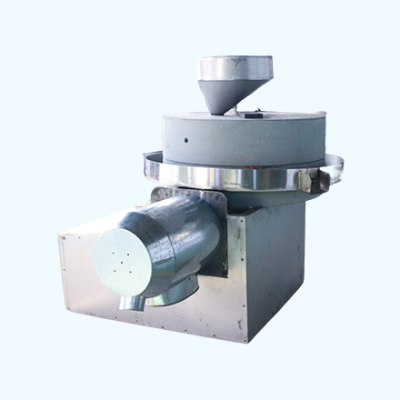

About us

YinChengtai (Shandong) Technology Development Co., Ltd. is a company engaged in engineering development, technical research, and experimental development. The company specializes in stone mill-related equipment, which is widely used in the fields of grain processing and medicinal material grinding. The company is committed to providing high-quality solutions to food processing enterprises with intelligent manufacturing equipment. With advanced production equipment and a technical team, the company adheres to the business philosophy of "survival by quality, development by reputation," always putting customer needs first and continuously innovating to provide better products and services.