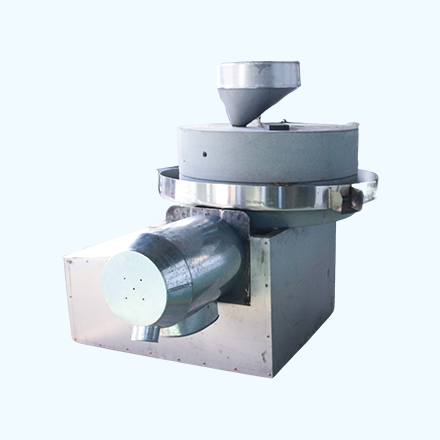

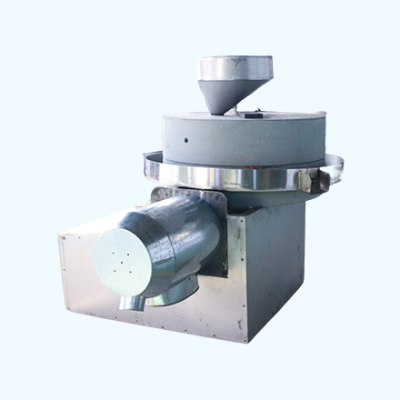

Cereal Grinding Machine

1. The stone used in the stone mill is non-toxic and non-radioactive, and contains minerals and trace elements.

2. The stone mill grinds at a low speed and is processed at a low temperature, which will not destroy the nutrients in the raw grain.

3. The stone mill can grind a variety of grains into flour.

4. Small size, light weight, and low power consumption.

Cereal Grinding Machine Product Description

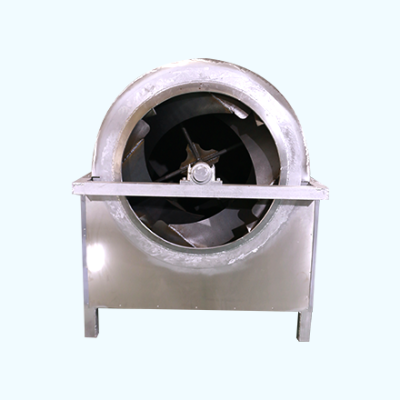

The grain stone mill is a kind of equipment designed for the needs of small and medium-sized flour production. It can efficiently process wheat and produce high-quality flour. The machine is usually composed of a fan, a wind collector, a vibration lifting and unloading device, etc., which can realize full air delivery and automatic cycle processing and grinding.

Features

1. Efficient grinding

The Cereal Grinding Machine adopts advanced flour making technology, optimizes the design of the grinding roller and the grinding gear structure to improve the crushing efficiency. It can process 50-300 kg of wheat per hour to meet the needs of different production scales.

2. High safety

The stone mill machine is equipped with multiple safety protection measures, including overload protection and automatic power-off device to prevent accidental damage caused by improper operation or equipment overload. The material contact parts meet food-grade safety standards to ensure that there is no secondary pollution in the production process.

3. Energy-saving and environmentally friendly design

The stone mill machine adopts an optimized motor transmission system, and the operating power is controlled between 5-15 kilowatts. The energy consumption is about 20% lower than that of traditional grinding equipment. At the same time, the internal structure design reduces dust leakage and the working noise is controlled within 65 decibels, providing a quiet and environmentally friendly working environment for production operations.

Sample

We have fully automatic flour mill and semi-automatic flour mill. Can meet the production requirements of different companies.

Application Scenario

1. Large flour mills

2. Flour processing

3. Home use

Parameter

Specifications(cm) | Voltage( V) | Power(kw) | Processing weight(kg) | Area(m) | Thickness(cm) | Weight(kg) |

| Jiaolong Flour80 | Customizable | 2.5 | 50-60 | 3*2*2.4 | 23/20 | 1000 |

| Jiaolong Flour100 | Customizable | 3.3 | 100 | 3*2*2.4 | 24/22 | 2000 |

| Fan single mill100 | Customizable | 6.0 | 100 | 3*2*3.2 | 24/22 | 2000 |

| Fan double mill100 | Customizable | 9.7 | 200 | 3.2*3.2*4 | 24/22 | 3000 |

Operation Working Video

Factory Show

Our company has stone raw material area, machine assembly and welding workshop, model room, etc.

How to maintain

1. Clean the gear commonly Equipment

During long-term use, dirt and impurities are without problems accumulated, affecting the running efficiency. After use, the feed port, crushing chamber, and discharge port have to be cleaned in time to keep away from accumulation of grain residues, inflicting blockage or mildew.

2. Check the put on of key components

Blades, screens, and bearings are the core running aspects of the equipment. Their put on immediately impacts the crushing impact and tools life. Check the sharpness of the blades and the integrity of the displays each and every month. If the blades are blunt or the monitors are damaged, they want to be changed in time.

3. Ensure the everyday operation of the motor

As the energy supply of the equipment, the overall performance of the motor is crucial. Check the running temperature and noise degree of the motor normally to keep away from harm to the motor due to overload or overheating. Perform a complete inspection of the motor each quarter, which include line connection, air flow system, and insulation, to make sure that the motor is in desirable condition.

4. Adjust tools parameters

The crushing fineness of the tools is typically completed by using adjusting the display screen or speed. During use, the parameters must be checked in many instances in accordance to the real processing desires to see if they are accurate, to keep away from long-term constant parameter operation ensuing in decreased processing effectivity or improved gear loss.

5. Prevent rust and corrosion

To lengthen the carrier existence of the equipment, the gear have to be positioned in a dry and ventilated surroundings to keep away from moisture inflicting rust on parts. For metallic components that are frequently in contact with uncooked materials, anti-rust oil or food-grade shielding coating can be utilized regularly.

6. Regularly substitute consumable parts

Some components of the equipment, such as seals and filters, are consumable components with excessive frequency of use. It is advocated to formulate a life like substitute cycle (such as alternative each 6 months) in accordance to the frequency of use of the gear to keep away from affecting the overall performance of the gear due to ageing of parts.

Our Company

Our company has been specializing in stone mills for more than 40 years. Welcome to inquire if you are interested.